Mikropor MK-HP Series Refrigerated Air Dryers & HP Series Compressed Air Filters

Compressed air systems used in industrial production lines are critical in terms of process safety, equipment life, and energy efficiency. Especially in high-pressure applications, preventing contamination from moisture and particles in the air requires optimized system designs, and if these contaminants cannot be eliminated, process efficiency is directly affected. Therefore, high-performance air dryers and filtration solutions are indispensable for a reliable operating infrastructure. Mikropor’s MK-HP and HP Series products are superior engineering solutions developed specifically for this need.

High-pressure air dryers and filters are used for many purposes in various industrial applications. Contaminants such as oil, water, and variational particles may be present in the compressed air produced by these systems. This damages compressed air system lines, pneumatic systems, and machine equipment. The main reason for this is that the compression process increases the amount of oil and water in the compressed air to levels that can damage the system.

Hot and humid air, in particular, has a higher moisture content than cold air. This causes more water to be discharged from the compressor. For example, a 55 kW screw air compressor operating at an ambient temperature of 24 °C and 75% relative humidity will produce 280 liters of water per day. Depending on the application, the water produced must be removed from the system because it can damage pneumatic components (valves, pistons, control systems, etc.) and cause corrosion in compressed air lines. Compressed air dryers are systems specifically designed to remove water from compressed air. Compressed air dryer types are listed below:

- Refrigerated Air Dryers

- Membrane-Type Air Dryers

- Adsorption-Based Dryers

With these dryers, the moisture level in the air can be reduced to the desired levels for the application. The dryness of the air coming out of the dryer systems is measured by the dew point. The dew point is the temperature at which the moisture in the air reaches 100% saturation. Thus, the maximum amount of moisture that air can carry at a given temperature is expressed by the dew point temperature. Obtaining dry air at the desired dew point can proportionally affect the costs incurred by the dryer systems. For this reason, selecting the right equipment for the compressed air drying process and solving the problem in the most economical way is important.

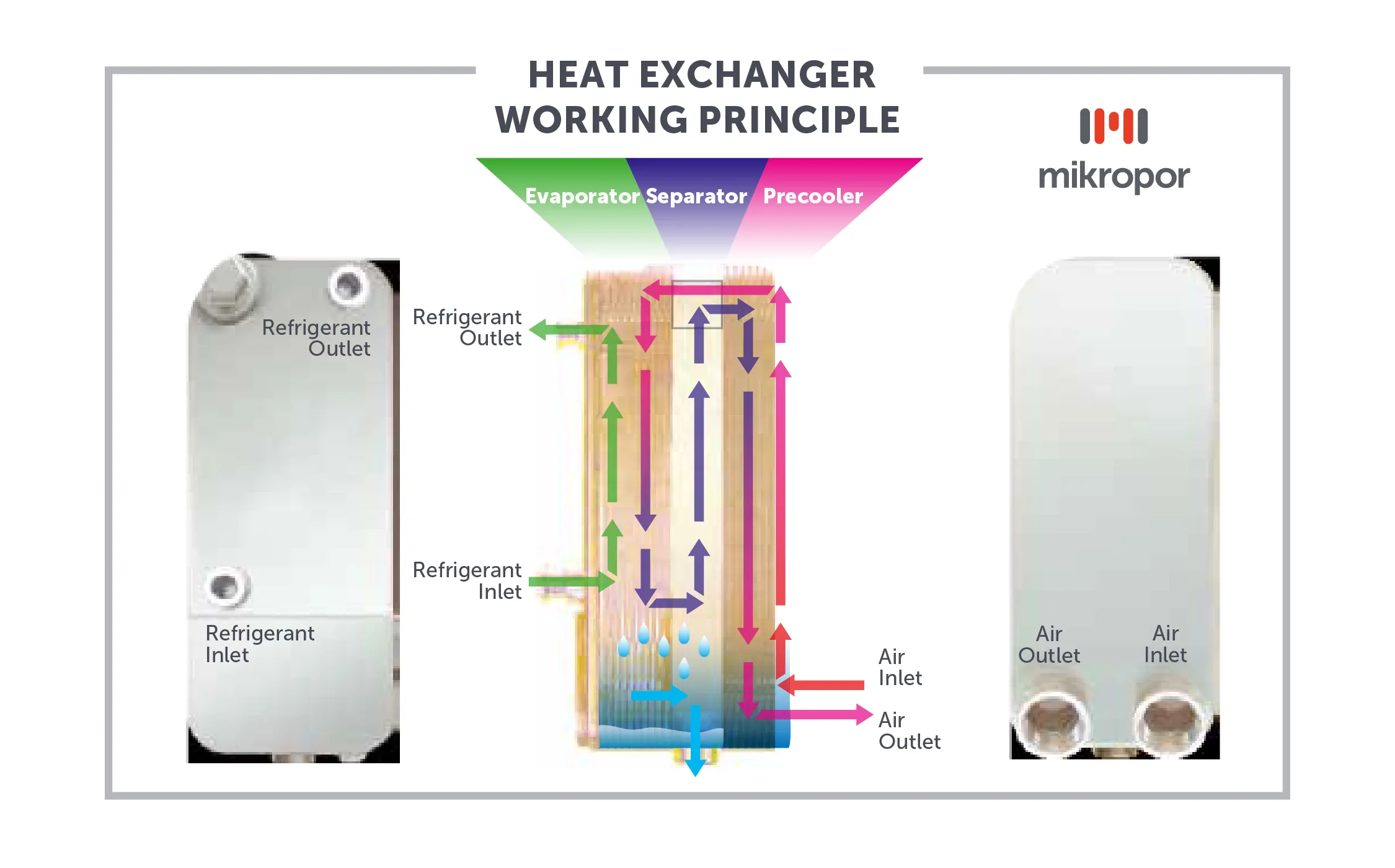

Refrigerated Air Dryers are the most commonly used compressed air dryers due to their cost and maintenance expenses being more favorable compared to other types of dryers. In these dryers, the compressed humid air first passes through an air-to-air heat exchanger, where the initial cooling process takes place. In the second step, the air is cooled by passing through heat exchangers together with a special refrigerant gas. This causes the moisture in the air to condense, and the condensed water is discharged through drains. The cooled air is then brought back to the appropriate temperature, and dry air with a dew point of 3°C is obtained at the dryer outlet. Since the refrigerant inside will freeze at temperatures below 0°C, a lower dew point cannot be achieved. Environmentally friendly and efficient gases such as R134a, R513a, and R1234yf are used as refrigerant gases.

The safe drying performance required for industrial applications demanding high pressure can be achieved with high-pressure dryers. Designed for use in these applications, the Mikropor MK-HP Series High-Pressure Air Dryers stand out with their highly compact design, unlike other refrigerated dryers, and can withstand operating pressures of up to 45 bar. , due to the moisture content in the air drying process, components such as heat exchangers in the air line have an anti-corrosion stainless steel material structure.

One of the important parameters in this type of electrically powered dryer is energy consumption. The latest technology in this regard is the three-in-one heat exchanger, which has a very low pressure drop. Mikropor offers pressurized air dryers with three-in-one heat exchangers to meet pressurized dry air needs at any capacity with its Cooled Type High Pressure Air Dryer.

Mikropor MK-HP Series High-Pressure Air Dryers feature stainless steel and brazed plate heat exchangers, consisting of an Air/Air heat exchanger (pre-cooler), Air/Refrigerant Gas Air Exchanger (Evaporator), and Water Separator in one module. The robust heat exchanger structure ensures high heat transfer, resulting in high performance and energy efficiency.

Air filters are integrated into the system for the filtration of compressed air. These filters are used to filter components such as oil, water, and particles present in the compressed air within the integrated system. The Micropor HP Series High-Pressure Air Filters are designed for high-pressure applications with a working pressure of 50 bar. These filters are highly resistant to pressure as they are weld-free and specially manufactured.

Air filters are integrated into the system for the filtration of compressed air. These filters are used to filter components such as oil, water, and particles present in the compressed air within the integrated system. The Micropor HP Series High-Pressure Air Filters are designed for high-pressure applications with a working pressure of 50 bar. These filters are highly resistant to pressure as they are weld-free and specially manufactured.

Achieving safe, efficient, and long-lasting solutions in high-pressure air systems is possible through the use of the right drying and filtration technologies. Mikropor MK-HP Series Refrigerated Air Dryers and HP Series High-Pressure Filters offer effective solutions for industrial needs with their compact structures, high pressure resistance, and energy-efficient designs. Click here to explore Mikropor’s compressed air dryers in detail, or click here to contact our expert sales teams.

Mikropor R&D Department