Oxygen is not only an important component of the atmosphere, but also indispensable for both human life and many critical areas of industry. Especially during the COVID-19 pandemic, it has become clear worldwide that oxygen is a vital necessity. Today, oxygen plays a critical role not only in the healthcare sector but also in food production, metal and glass processing industries, advanced technology applications, energy systems, and even in aerospace fields such as jet and rocket engines to obtain powerful fuel mixtures. This wide range of uses, from sustaining life to high technology, once again highlights the strategic importance of oxygen. That is precisely why on-site oxygen production solutions are becoming increasingly important today for the reliable, economical, and sustainable supply of oxygen.

What Are the Methods of Oxygen Production?

Oxygen gas is produced using three primary methods:

- Cryogenic Separation

Gases in the air are separated by utilizing their different boiling points. However, since oxygen has a boiling point of -297.2°F, liquefying and storing it is quite challenging. Despite specialized tanks, the tendency of liquid oxygen to revert to its gaseous state leads to both production losses and costly logistics processes. - Membrane Technology

Air gases are separated based on their diffusion properties using special fibers. However, the purity of oxygen obtained by this method generally remains between 25–40%. Therefore, it is preferred for applications requiring lower purity. - PSA (Pressure Swing Adsorption) Method

This is the most widely used method today. It offers an economical and reliable solution thanks to its low energy consumption, high purity rate (90–95%), and on-site production capability.

How Does the Pressure Swing Adsorption (PSA) Method Work?

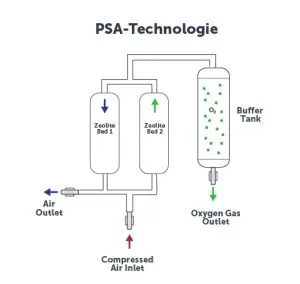

The Pressure Swing Adsorption (PSA) method is one of the most preferred technologies for on-site oxygen production today. In this method, the process begins with the compression of air using compressors. The compressed air is directed to tanks filled with specially selected zeolite granules. Zeolite strongly traps nitrogen molecules on its surface due to its porous structure, allowing oxygen to be released.

PSA systems typically consist of two tanks that operate cyclically:

- While one tank is actively producing,

- The other tank enters the regeneration process, allowing the zeolites to become reusable.

The regeneration process begins with a reduction in tank pressure; nitrogen and other gas molecules trapped on the zeolite surface are expelled. This reactivates the granules, preparing them for oxygen production in the next cycle. This reciprocating system ensures an uninterrupted, reliable, and continuous flow of oxygen. PSA technology has the capacity to produce oxygen with 90–95% purity when implemented in a properly designed system.

This method stands out not only for its high purity but also for its energy efficiency and low operating costs. Furthermore, the process being fully under automatic control provides the user with a safe and stable production process.

What Are the Advantages of On-Site Oxygen Production?

On-site oxygen production eliminates the costs and risks associated with the production, storage, and transportation of liquid oxygen. Storing liquid oxygen in special tanks is technically difficult and involves constant losses. Furthermore, the need for additional equipment such as filling, transportation, and manifold systems places both financial and operational burdens on businesses.

In contrast, PSA-based on-site production systems enable the oxygen required to be produced directly within the facility, on demand and in the required quantity. This approach means an uninterrupted and reliable oxygen source, especially for businesses operating in healthcare facilities, food production plants, metal and glass processing factories, power plants, and high-tech fields.

On-site production also offers:

- Cost advantage: Eliminates transportation, filling, and intermediate storage costs.

- Operational convenience: Reduces user dependency through continuous and automated production.

- Safety: Minimizes the high risks associated with storing liquid oxygen.

- Sustainability: Provides environmental benefits by reducing energy consumption and logistical requirements.

As a result, on-site oxygen production has become one of the most reliable solutions for modern industries and healthcare systems, both economically and strategically.

On-Site Reliable Oxygen Production with Mikropor Oxygen Generators

Mikropor has become a reliable global brand in industrial filtration and gas production through its innovative engineering approach and strong R&D efforts. Thanks to its commitment to international quality standards and its constantly evolving technologies, Mikropor solutions are now preferred in many countries around the world.

Mikropor Oxygen Generators (MOG) combine the advantages of PSA technology with maximum efficiency. This allows businesses to produce uninterrupted oxygen with 90–95% purity at their own facilities, under reliable, economical, and sustainable conditions. Energy savings, low operating costs, durable design, and continuous innovative developments make the MOG Series unique.

From healthcare to food production, from metal and glass processing industries to advanced technology fields such as aerospace, the MOG Series Oxygen Generators, developed with Mikropor’s expertise, are the most reliable solution for on-site oxygen production across a wide range of applications. Click here to explore our products, or click here to contact our expert sales teams.

Mikropor R&D Department