The automotive industry involves a series of processes that must be carried out with the utmost precision at every stage. The basic processes involved in manufacturing a car include production, assembly, inspection, and testing.

Mikropor offers its automotive industry customers tailored solutions at every stage of production through its products.

In this article, we will discuss the automotive painting process, which is directly inspected by customers when purchasing a vehicle, significantly influences the impression the vehicle makes on the customer, and determines the vehicle’s color, as well as the Mikropor products used in this process.

The main reason why the vehicle painting process is the most important process for both customers and vehicle manufacturers is that it is the first detail customers see. The visual perfection of the vehicle is directly proportional to the successful completion of the painting process.

To ensure that the painting process is completed successfully, the automotive painting process is divided into several main sections. These main sections are as follows: pre- treatment and cathodic dip coating, sealing applications, primer, and topcoat applications. These main sections are further divided into a series of sub-processes.

Although the primary purpose of automotive paints is to provide a shiny and attractive appearance for customers, one of the most important objectives of the painting process for manufacturers is to protect the vehicle body from weather conditions and corrosion. Details such as visual appeal and corrosion protection necessitate that the automotive painting process be carried out under specific standards and result in a high-quality output.

Automotive Painting Process

Pre-Treatment and Cathodic Electrocoating

The first stage in the car body painting process is cathodic dip coating. The main purpose of this coating is to cover the car body with a protective layer against weather conditions and corrosion. For the cathodic dip coating process, the car body must undergo a series of processes. These processes are typically carried out in large tanks where the entire vehicle body is immersed, with separate compartments for each process.

Before cathodic electrocoating, the vehicle body to be painted undergoes a preparation phase consisting of several steps. These preparation steps are as follows: removal of the oxide layer, degreasing, rinsing, phosphating, and rinsing again. After these processes, the vehicle body is ready for cathodic electrocoating. The main reason for performing these processes is to prevent any external contaminants on the vehicle body from remaining on the body before the coating process. After these processes, the cathodic electrodeposition coating process is applied to the vehicle bodies in the cathodic electrodeposition tank so that it penetrates the internal and external cavities. After the cathodic electrodeposition coating process, a final rinsing process is performed, and the vehicle body is transferred to the drying oven. The vehicle exiting the drying oven is then sent to the sealing applications section for further processing.

The purpose of using drying ovens in both cathodic electrocoating and other processes such as primer/topcoat painting is to ensure that the protective layer of the applied coating/paint hardens, crystallizes, and adheres firmly to the surface.

Sealing Applications

After the cathodic dip coating process, which protects the vehicle body from weather conditions and corrosion, is completed, the next step is to perform the sealing processes on the vehicle.

At this stage, waterproofing steps are applied to provide insulation against heat, sound, and liquids for the vehicle body.

Primer and Topcoat Painting Applications

Vehicle bodies that have undergone cathodic dip coating and sealing applications are sent to primer and top coat painting booths, which constitute another important stage of the painting process. The booths where primer and top coats are applied are among the most important areas of automotive paint shops. These environments must be free of dust, particles, and other contaminants that can cause quality defects.

Before entering the primer paint booth, the vehicle body is cleaned with an air curtain or cleaning brushes to prevent particles from the external environment from remaining on the surface to be painted and being carried into the paint booth. In the first stage, the primer paint is applied to the vehicle body using robots. After the primer paint process is completed, the final coat of paint is applied using robots.

After the painting process is completed, the vehicle is sent to the paint drying oven. High temperatures are used to harden the paint and ensure it adheres to the surface.

Quality Control Applications

Vehicles exiting the paint drying oven are visually inspected by quality control units. Defects specified by quality standards are checked under intense lighting. Any defects are repaired through touch-up processes, and the vehicle is sent to the assembly department.

Mikropor Products in the Automotive Industry

Work environments in automotive paint shops are divided into specific groups. This classification is determined based on the dust and particle sizes that may be present in the environment. The environments and cabins where processes are carried out in paint shops are generally provided by air conditioning systems that filter the air taken from the atmosphere and send it to the work environment.

It is not possible to make a generalization about filters used in air conditioning systems for automotive companies. Many variable parameters, such as the standards applied by the company, the location of the factories, and the particle density of the air taken from the atmosphere, prevent us from making a generalization based on the sector.

Our work at Mikropor focuses on determining the correct filters for the company’s needs using our filters suitable for the automotive industry.

Since automotive companies engage in serial and continuous production, offering solutions with filters that have a long service life, low pressure drop, and high energy efficiency is important for both our customers and us.

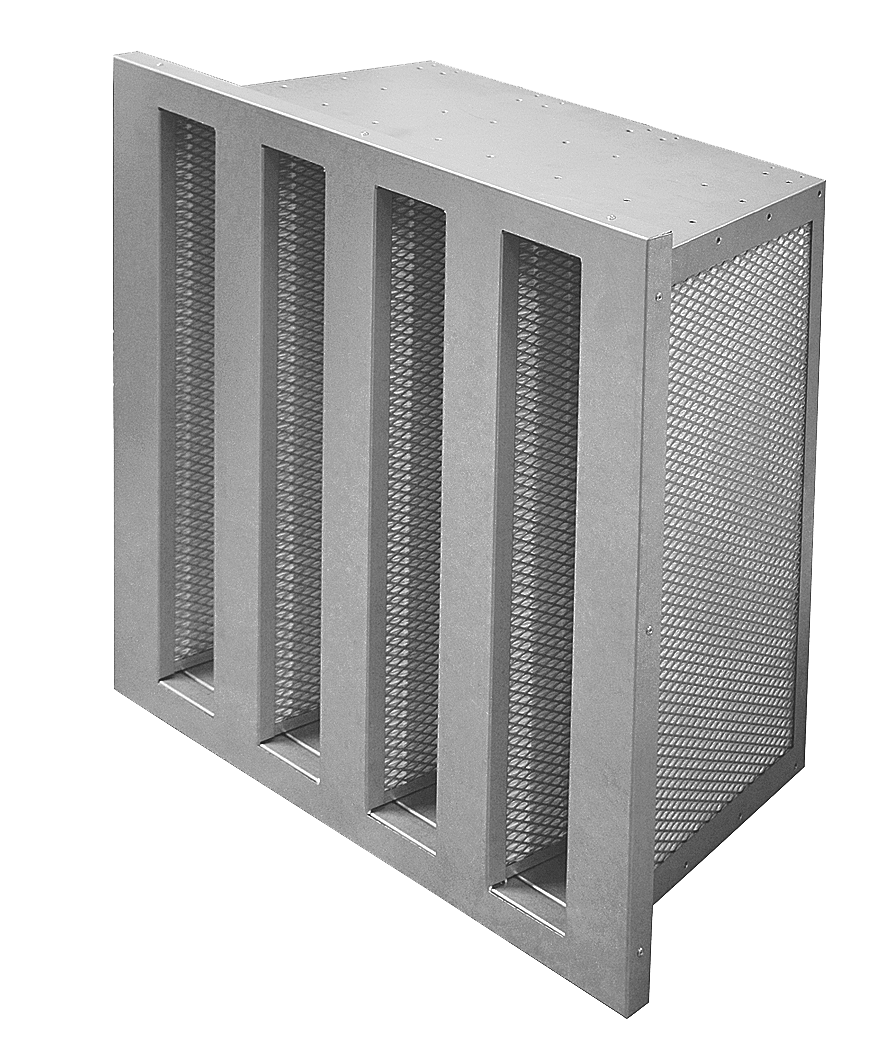

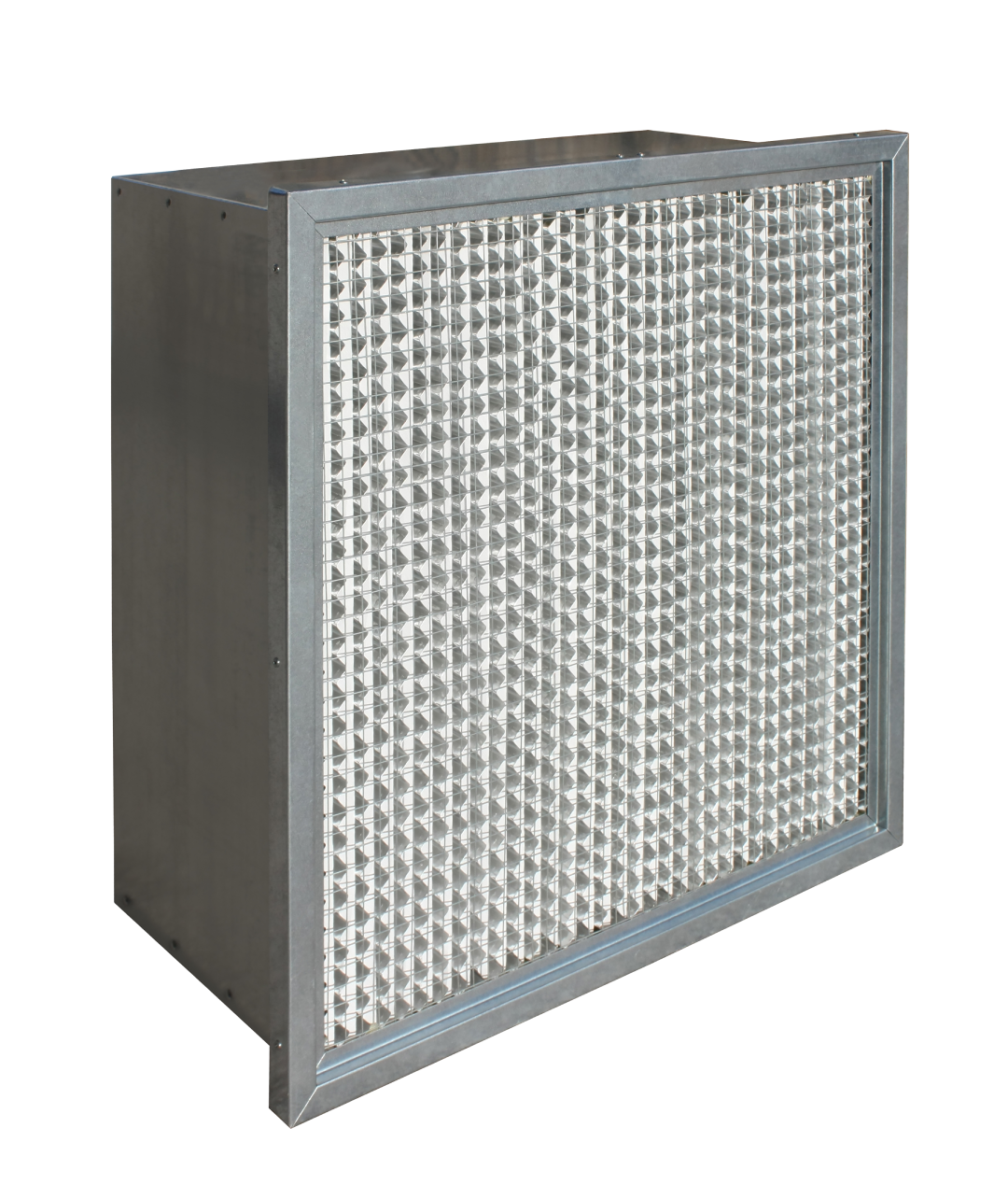

With our MPR Series bag filters and MV Series V filters, we achieve long-term use, low pressure drop, and high-quality output for the air conditioning systems used in automotive companies’ paint shops. Our high-temperature filter products, MASHT, MPHT, and MV4HT, are other products that enable us to achieve the same output in paint drying ovens.

In our next article, you will find out which processes our products for the automotive industry are used in, the benefits they provide to our customers, and why filters are important for the automotive painting industry.